Steel/INOX Burr: Eradicate the needs for constant tool changes

The new cut profile of the Z42 INOX and steel burr cuts the two most important materials quickly and reliably. The robust tooth geometry with faceting prevents chipping and guarantees high stock removal rates. This helps you save time and equipment costs. The improved chip breaker allows you to work even more ergonomically. Whilst achieving the best surface finish yet.

Properties

- High chip removal thanks to a coarse cut. Ideal when time is of utmost importance.

- Faceted teeth for perfect surface results.

- A smooth running, low-vibration tool without chatter thanks to the improved cutting angle.

It is within the foundry industry that this type of burr will typically be used. Due to the aggressiveness of this burr, large amounts of stock can be removed. The benefit of this does not have a negative impact on the tool life. In comparison to a mounted point, our Steel/INOX burr offers a much more aggressive cut while typically ensuring increased tool life. This tool has proven to be important because it allows only one type of burr to be used on both steel and stainless steel. In turn, this eradicates the need to have various burrs available.

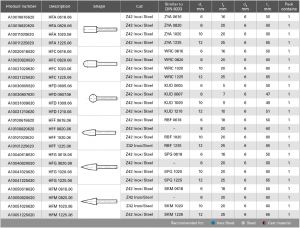

A large range of INOX/Steel burrs are now available ex-stock Germany. Newly developed shapes and sizes have recently been added to our range due to the success of this burr.

In addition to the above range, if a specific requirement is raised that cannot be supplied from stock. Our highly reputable burr department are able to manufacture specific shapes and sizes to suit most requirements. Kayson Green Limited work closely with both the customer and our burr department during this process. This ensures all technical parameters have been discussed and understood.

For full details relating to Lukas flexible grinding tools, please click here.

Please contact Kayson Green’s head office or your Kayson Green technical sales representative for more details.